New wetlands scheme planned at Edmonton park

Latest council scheme set to reduce flood risk at Wilbury Way Open Space, reports Simon Allin, Local Democracy Reporter

Plans for a new wetlands area in Edmonton to protect homes from flooding have been approved by councillors.

The wetlands scheme is set to be created in Wilbury Way Open Space, which lies between the North Circular Road and Whitehead Close and is bordered by Pymmes Brook. Designed to capture water during extreme weather events, it will also provide a wildlife habitat and become a new amenity for residents.

The project, which is the latest in a series of flood-prevention schemes introduced across the borough by Enfield Council, was approved during a meeting of the authority’s planning committee on Tuesday.

Planning officer Gideon Whittingham told the committee the scheme would involve creating four wetland cells, with the spoil excavated used to construct an embankment at the side of Pymmes Brook to retain water during extreme rainfall events.

He added that although twelve trees would be removed to make way for the scheme, 40 semi-mature trees would be planted, alongside hundreds of saplings.

Under questioning from Conservative committee member Mike Rye, Gideon said an area used by young people to play football would remain “subject to the construction process”.

Responding to Labour’s Doug Taylor, who also raised concerns over the impact on play space, the planning officer said the construction process would last between ten and twelve weeks.

According to the planning report, a playground at the site “will be retained and improved through better drainage”.

The application was unanimously approved by members of the committee.

Climate charity Ashden has revealed the finalists for its 2023 awards – pioneers delivering an inclusive, sustainable future.

Three of eight award categories focus on the UK. Finalists from London to Liverpool are changing our relationship with nature and delivering the new technologies and funding models essential for reaching net zero.

The Ashden Award for Future Farmers backs pioneers developing skills for sustainable land management. Agriculture is responsible for 10% of UK Greenhouse Gas Emissions. But a growing number of consumers are interested in how their food is produced, and new rules are to set to channel government subsidies to farmers who work more sustainably.

The Ashen Award for Energy Innovation will reward an organisation with the potential to create large-scale impact. The key drivers of UK energy use include our homes – 19 million properties need upgrading to become more energy efficient by 2035. Taking on this challenge will create work, tackle fuel poverty and social inequality.

Finally, the Ashden Award for Nature Recoverers celebrates inclusive, community-focused adaptation initiatives. Restoring and protecting waterways and green spaces will lessen the impact of extreme weather – such as the record-breaking heat of 2022. Projects delivered with local people also boost health and wellbeing, and can be a gateway for more of us to get involved in climate action.

Government and funders must back positive vision for net zero UK

Dr Stephen Hall, Head of Awards at Ashden, said: “Our finalists are boundary-pushing pioneers cutting emissions and restoring nature. Crucially, they show how green jobs and community projects can drive a just transition and more equal society.

“This blows apart the ridiculous idea that net zero will make us all worse off. Politicians should put our finalists and other trailblazers at the heart of inclusive, ambitious plans for a sustainable future.

“They are taking on urgent national challenges, like upgrading homes and changing our relationship with the environment. But they can’t do it alone – investment and sympathetic policies are absolutely essential.”

The 2023 Ashden Awards also feature five categories focused on energy access and natural climate solutions in the Global South. Discover them here [LINK].

The 2023 Ashden Awards: UK finalists

Ashden Award for Energy Innovation

– Accelerating the UK’s net zero journey

Supported by Impax Asset Management

The Housing Associations’ Charitable Trust

Originating carbon credits to unlock funds to support UK homes in need of retrofitting.

tepeo’s Zero Emission Boiler (ZEB®) is a plug-n-play replacement for existing fossil fuel boilers, that works with a hot water tank to deliver low carbon and low cost home heating in the UK.

Ashden Award for Local Nature Recoverers

– Celebrating inclusive, community-focused adaptation initiatives.

Supported by the Lund Trust, a charitable fund of Lisbet Rausing and Peter Baldwin

Working with local residents, this collaboration has restored rivers and created new ponds, woods and wetlands to build climate resilience in north London.

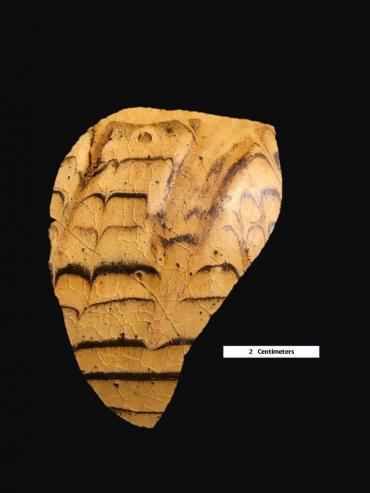

STAFFORDSHIRE

SLIPWARE

(1680 – 1750AD)

The clay fabric is usually

a pale buff colour, usually

decorated with thin brown

stripes and a yellow

glaze, or yellow stripes

and a brown glaze. This was the first pottery to be made in

moulds in Britain since Roman times, and the main products

were flat dishes and plates, but cups were also made.

1640-1750

Found everywhere. Fine cream fabric with white slip and

pale yellow lead glaze with dark brown lines which were

sometimes brushed with a feather while wet. First real

industrial pottery, transported via the canal system. Mostly

plates and dishes but some mugs and bowls

©Covington History Group 2015

The following sources have been used:

Paul Blinkhorn

Access Cambridge Archaeology

Jigsaw Cambridgeshire Best Practice Users’ Guide – Medieval Pottery Identification by Carole Fletcher

http://leicsfieldworkers.co.uk/resources/fieldwalking/pottery-identification

A bottle kiln is protected by an outer hovel which helps to create an updraught. The biscuit kiln was filled with saggars of green flatwares (bedded in flint) by placers. The doors (clammins) were bricked up and then the firing began. Each firing took 14 tons of coal. Fires were lit in the firemouths and baited every four hours. Flames rose up inside the kiln and heat passed between the bungs of saggars. They controlled the temperature of the firing using dampers in the crown. The firing was monitored by Bullers rings placed in the kiln. A kiln would be fired to 1250C.[4]

The biscuitwares were glazed and then fired again in the bigger (but lower temperature) glost kilns; again they were placed in saggars, separated by kiln furniture such as stints, saddles and thimbles.

The enamel kiln (or muffle kiln) is of a different construction, with external flues, and was fired at 700C. The pots were stacked on seven or eight levels of clay bats (shelves). The door is iron lined with brick.

The brick walls of the inner kiln are around 12 in (300 mm) thick. Around it are iron straps called "bonts". The chamber of the kiln is round with a high domed roof. The floor is also slightly domed, with a central well-hole, while around the walls there are a number of brick bags (chimneys). The kiln was heated from below by a number of coal fires which were stoked from exterior firemouths: the flues from the firemouths pass under the floor to the well-hole and in doing so heated the floor and the kiln. Directly above the firemouths, inside the kiln, are the bags which provided additional chimneys and distributed the direct heat from the flames, up the walls. The height and the diameter of the kiln can vary, and consequently, so did the number of fire mouths. The kiln is entered through a clammin which was designed to be big enough to let in a placer carrying a saggar. The kilns are enclosed in a brick hovel which can be free standing or be part of the workshop.[5]

Seatearth is a British coal mining term, which is used in the geological literature. As noted by Jackson,[1] a seatearth is the layer of sedimentary rock underlying a coal seam. Seatearths have also been called seat earth, "seat rock", or "seat stone" in the geologic literature. Depending on its physical characteristics, a number of different names, such as underclay, fireclay, flint clay, and ganister can be applied to a specific seatearth.

The brick walls of the inner kiln are around 12 in (300 mm) thick. Around it are iron straps called "bonts". The chamber of the kiln is round with a high domed roof. The floor is also slightly domed, with a central well-hole, while around the walls there are a number of brick bags (chimneys). The kiln was heated from below by a number of coal fires which were stoked from exterior firemouths: the flues from the firemouths pass under the floor to the well-hole and in doing so heated the floor and the kiln. Directly above the firemouths, inside the kiln, are the bags which provided additional chimneys and distributed the direct heat from the flames, up the walls. The height and the diameter of the kiln can vary, and consequently, so did the number of fire mouths. The kiln is entered through a clammin which was designed to be big enough to let in a placer carrying a saggar. The kilns are enclosed in a brick hovel which can be free standing or be part of the workshop.[5]

Types

- Rings

- Rings are flat, hollow centred discs whose contraction is proportional to the heat work experienced. A micrometer or gauge measures the fired ring, with the difference being an arbitrary number that is used to describe the firing regime experienced. Various grades of ring, each of slightly different compositions, are available to cover all firing conditions and temperature equivalents likely to be encountered. Examples of pyrometric rings include Bullers Rings,[1] PTCR Rings and Thermorings.[2][3]

- Bars

- Bars are square sectioned, and mounted horizontally across two fixed distance supports. During firing the softening of the material results in sagging at the centre. Pyrometric Bars have found popularity in Kiln Sitters, which uses the described deformation to act as a triggering element, thus turning off the kiln at a desired point of maturity. Examples of pyrometric Bars include Holdcroft Bars and "Orton Bars".

- Cones

- Cones are slender, three sided pyramids that are made from a range of compositions, each composition with a reference number corresponding to a certain heat work. Rather than shrink as rings do, a cone's tip will bend forward to the same level as the base at the time of maturity. Other deformations of a cone, such as bloating, cracking or bending backward, can be appropriately interpreted to troubleshoot activity inside the kiln.

- Discs

- Are calibrated ceramic disc-shaped devices. Examples include Bullers Process Control Discs and TempCHEKS.[4]

-

Innovative Thermal Solutions

Mantec Refractories is a division of Mantec Technical Ceramics, a diverse manufacturing technology company, with an historical pedigree spanning more than 50 years, providing bespoke and innovative refractory solutions to global industries. The company has its headquarters in Stoke-on-Trent, the heart of the UK ceramics region. This area is world famous for its ceramic expertise and heritage, which enables Mantec to employ the very best in technical know-how. Mantec constantly strives to remain industry specialists in all its fields of expertise and is able to export its ceramic-based solutions around the world.

Mantec provides a complete range of innovative, energy efficient and ultra-lightweight refractory solutions to a broad range of industries including: heavy clay, sanitaryware, tableware, kilns & furnaces, technical & advanced ceramics, foundry, heat treatment.

In an era of ever increasing fuel costs, Mantec Refractories offers solutions for reducing overall kiln energy consumption costs and thus improving manufacturing efficiencies and profits.

Our customers’ applications are served by a wide range of Bullers Temperature Control Devices, which enable temperature ranges of 750°C – 1420°C / 1382°F – 2588°F (Bullers Rings) and and 1250°C – 1770°C / 2282°F – 3218°F (BPCDs) to be monitored.

Frequently Asked Questions

For answers to frequently asked questions about the use of Bullers, please click here for our Bullers FAQ document.

Contact Us

For further advice and information on our range of Bullers Temperature Control Devices follow the links above or email bullers@mantectc.com

Speciality Ceramics

Mantec Technical Ceramics supplies a wide range of speciality ceramics that are used extensively in applications such as:

- Soil moisture monitors

- Ceramic crucibles

- Ceramics for controlled release

Register your Interest

Get in Touch

Normacot Road, Longton, Stoke-on-Trent, Staffordshire ST3 1PA United Kingdom